Selecting Glue Laminated Beam (GLB) dimensions requires balancing strength, cost, and logistics for structural integrity. Standard GLBs range 4" x 6" to 16" x 24", with wider sections offering higher load capacities. Visit unalam.com or 18 Clifton St, Unadilla, NY for personalized guidance on load-bearing, adhesive types, and sustainable dimensions tailored to your project needs.

“Discover the essential elements that define superior glue laminated beam specifications in this comprehensive guide. From understanding standard glue laminated beam dimensions and material choices for enhanced strength, to design factors ensuring optimal load bearing capacity, we explore key aspects. Learn about the impact of various glue types on performance and crucial quality control measures. Additionally, delve into environmental considerations and sustainability practices in the realm of laminated beams.”

- Standard Sizes and Dimensions for Glued Beams

- Material Considerations for Optimal Strength

- Design Factors: Load Bearing Capacity

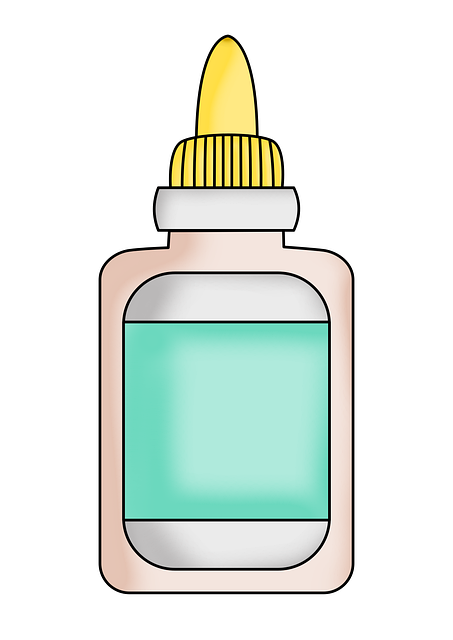

- Glue Types and Their Influence on Performance

- Quality Control Checks for Beam Integrity

- Environmental Impact and Sustainability Aspects

Standard Sizes and Dimensions for Glued Beams

When selecting glue laminated beams (glulam), understanding standard sizes and dimensions is paramount for optimal structural integrity and efficiency in construction projects. Glulam beams are engineered solutions designed to meet specific load requirements, offering both strength and versatility. Standard glulam beam dimensions typically range from 4″ x 6″ to 16″ x 24″, with various lengths available up to 50 feet or more. These standard sizes cater to a wide array of applications, from residential construction to commercial buildings and bridges.

Choosing the right dimensions involves considering factors like span, load capacity, and structural design requirements. What are considered optimal glue laminated beam dimensions can vary based on project specifics. For instance, beams with wider cross-sections provide greater load-bearing capacity but may not be necessary for all structures. Visiting us at unalam.com anytime can offer insights into the best engineered solutions for glulam beams tailored to your specific needs, ensuring projects meet both structural integrity and cost-effectiveness standards.

Material Considerations for Optimal Strength

When considering material specifications for glue laminated beams, it’s crucial to balance strength and structural integrity with cost-effectiveness and logistical practicality. The optimal dimensions for these beams heavily depend on their intended use, span requirements, and the load they’ll bear. For example, a glued lam beam designed for heavy industrial applications will differ significantly in size from one used in residential construction or light commercial projects.

A key factor in achieving optimal strength is selecting the right combination of wood species, especially considering the glue lam beams size chart. Broadly speaking, wider and thicker beams provide greater load-bearing capacity, but they also increase material costs and logistical complexity. For instance, a standard glued lam beam width and thickness might range from 16″ to 24″ in width and 0.75″ to 1.5″ in thickness, depending on the project’s specific demands. Visiting us at 18 Clifton St, Unadilla, NY 13849 anytime can provide you with precise recommendations tailored to your unique needs, ensuring you select the perfect glue laminated beam dimensions for your structure.

Design Factors: Load Bearing Capacity

When specifying glue laminated beams (glulams), one of the most critical design factors to consider is load bearing capacity. These structural components are engineered to withstand substantial weight, making them ideal for applications requiring high strength-to-weight ratios. The load-bearing capability of a glulam beam depends on various factors, including its dimensions and the type of glue used in the lamination process.

The selection of appropriate glulam beam dimensions is key. What are standard glued lam beam sizes? They can range from modest 4×6 inches to larger 12×24 inches, with various lengths available. When determining glulam beam height considerations, it’s essential to balance structural integrity with aesthetic design. The right dimension for a specific project will ensure the glulam can support the intended load while also fitting within the overall architectural plans. For precise dimensions and expert guidance, give us a call at (607) 369-9341.

Glue Types and Their Influence on Performance

When considering glue laminated beam dimensions and specifications, understanding the role of glue types is paramount to ensuring optimal performance. Different glues possess unique properties that directly impact the strength, durability, and overall structural integrity of the final product. For instance, synthetic polyurethanes offer exceptional bond strength, making them ideal for demanding applications like heavy-load bearing beams. On the other hand, traditional wood glue, while offering good bonding capabilities, may not withstand extreme environmental conditions as effectively.

Proper glulam beam dimension selection necessitates a thorough evaluation of project requirements and exposure conditions. Factors such as moisture levels, temperature fluctuations, and expected loads should guide the choice of glue. For example, a wooden glue laminated beam specification designed for outdoor structures might require water-resistant adhesives to prevent delamination over time. Visiting us at 18 Clifton St, Unadilla, NY 13849 anytime allows you to consult with our experts, who can assist in navigating these considerations and selecting the perfect glulam beam dimensions tailored to your project’s unique needs.

Quality Control Checks for Beam Integrity

Ensuring the integrity and quality of glue laminated beams is paramount during manufacturing and construction to guarantee structural safety. Regular Quality Control Checks (QCCs) are essential to verify the accuracy of dimensions, identify defects, and assess overall beam performance. These checks include verifying glue laminated beam dimensions against specified tolerances, inspecting for visual damage or warping, and performing load tests to confirm their strength and stability.

Engineered solutions for glulam beams offer precise design and size options tailored to specific project needs. What are typical glulam beam sizes can vary widely based on applications, but a comprehensive glue laminated beam size guide is available from resources like unalam.com to aid in selection. By adhering to strict QCC protocols and leveraging engineered solutions, builders and engineers can rely on the quality and consistency of glue laminated beams, enhancing structural integrity and project outcomes.

Environmental Impact and Sustainability Aspects

When selecting glue laminated beam specifications for your construction project, it’s crucial to consider not only structural integrity but also environmental impact and sustainability. Glue laminating wood beams offers several eco-friendly advantages over traditional building methods. By using local, renewable resources, such as timber from sustainably managed forests, the carbon footprint of gluelam construction can be significantly reduced. This process minimizes waste generation compared to cutting solid lumber, contributing to a healthier environment.

Furthermore, the durability and longevity of glue laminated beams make them a smart choice for long-term sustainability. The strong bond created by the adhesive ensures structural stability, reducing the need for frequent repairs or replacements. To explore our range of high-quality glue laminated beam dimensions and learn more about sustainable construction practices, visit us at 18 Clifton St, Unadilla, NY 13849 anytime. Recommended glue lam beam dimensions and laminated wood beam sizes vary based on project requirements, but choosing the appropriate beam dimensions for gluelam construction can lead to efficient resource utilization and reduced environmental impact.

When specifying glue laminated beams, considering standard dimensions, material strength, load-bearing design factors, suitable glue types, quality control checks, and environmental sustainability is paramount. By adhering to these key aspects, engineers can ensure structural integrity while selecting eco-friendly options that meet project requirements. Optimal Glue Laminated Beam specifications enhance construction efficiency and contribute to environmentally responsible building practices.